A unique filter media

Vidromar is an advanced filter media made from recycled virgin glass sand, designed exclusively for water filtration.

Simply replace the existing filter media with VIDROMAR to optimise the performance of any standard sand filter.

A unique filter media

Vidromar is an advanced filter media made from recycled virgin glass sand, designed exclusively for water filtration.

Simply replace the existing filter media with VIDROMAR to optimise the performance of any standard sand filter.

Maximum performance, Minimum consumption

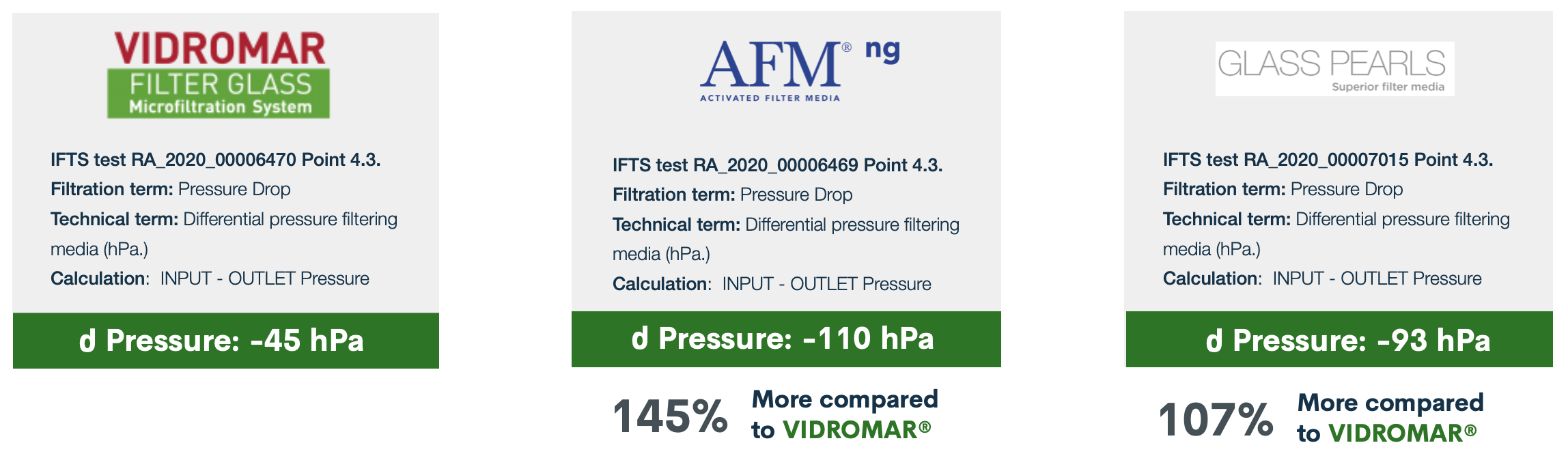

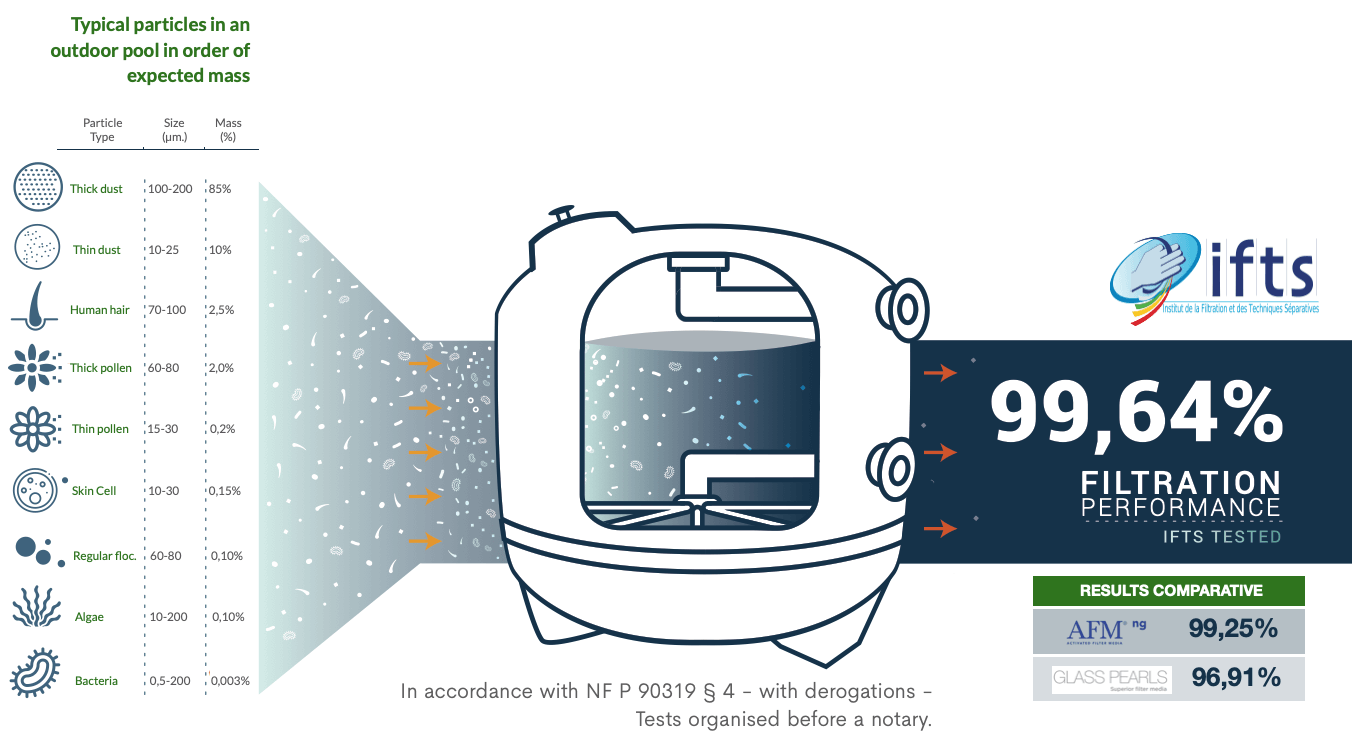

VIDROMAR offers a perfect balance between the highest particle retention in the pool filter, while achieving greater water and energy savings than any other filter media tested*.

*Results based on tests carried out by IFTS French laboratories.

Maximum Performance, Minimum Consumption

VITRAFIL® provides the perfect balance between the highest particle retention in the pool filter, while saving more water and energy than any other filter media tested*.

*Results based on tests carried out by the French IFTS laboratories.

Suitable for all sand filters

It is an advanced filter media made from recycled virgin glass, designed exclusively for water filtration.

Simply replace the existing filter media with VIDROMAR to optimise the performance of any standard filter.

Suitable for all sand filters

It is an advanced filter media made from recycled virgin glass, designed exclusively for water filtration.

Simply replace the existing filter media with VIDROMAR to optimise the performance of any standard filter.

Unique benefits for your pool

With VIDROMAR filter media, you can enjoy immediate benefits in the following areas

PERFORMANCE

EFFICIENCY

HYGIENE AND BIOSECURITY

SAFETY

DURABILITÉ

The effectiveness of VIDROMAR is based on the removal of the most common particles that can be found in a swimming pool and that cause the water to fog up. This maximizes both savings and efficiency. We achieve this through a highly selected grain curve and grain surface treatment technology, which allows us to avoid biofilm, keep the microchannels open and make the handling of particles completely safe.

ENERGY SAVING

Anti-Compaction Technology® is designed to keep the micro-channels of the filter media open, so that the pressure loss is negligible. As a result, the pump runs more smoothly and therefore reduces consumption:

WATER SAVING

At the same time as we save energy by keeping the microchannels open, we also save water by reducing the need for backwashing:

In order to inform users correctly, we contacted the Swiss laboratories Bioexam AG, which carried out a battery of tests for bacterial presence. In this way, we can verify the different biosafety levels of the most representative brands on the market:

A BASIC QUALITY

A BASIC QUALITY

Safety is a fundamental quality when it comes to products used in the treatment of water for human use. For this reason, at VIDROMAR we subject our glass to an advanced micro-polishing process to eliminate sharp edges.

This process results in a glass that is harmless and completely safe to handle.

ANTI-COMPACTION TECHNOLOGY

ANTI-COMPACTION TECHNOLOGY

Most filter media available on the market reach the end of their useful life prematurely due to compaction, a process in which the segregation of fine and coarse grains blocks the microchannels of the filter media.

To avoid this result, VIDROMAR has developed Anti-Compaction Technology®, a precise selection of grain sizes designed to extend the life of the media indefinitely.

ONLY ONE LAYER IS NEEDED

VIDROMAR only needs one layer, with one grain size, to provide maximum performance, unlike other filter media that require several layers of different grains to be effective.

This means that VIDROMAR can be used over and over again. If it needs to be removed for any reason, for example if the filter is damaged or the water traps are changed, it can be easily and safely removed and reused.

SUSTAINABLE MATERIALS

SUSTAINABLE MATERIALS

♻️ VIDROMAR is committed to sustainability and reducing its environmental footprint. For this reason, since its inception, we have worked with FSC-certified packaging, thus avoiding the use of thousands of kilograms of plastic.

In addition, VIDROMAR is produced from recycled virgin glass and contributes to a significant reduction in energy and water consumption in swimming pools around the world.

And we continue to work every day to implement intelligent and sustainable solutions at every stage of production.

Remplissez à moitié le filtre vide avec de l’eau pour protéger les buses.

Remplissez le filtre avec un poids de VIDROMAR inférieur de 20% à la recommandation du fabricant du filtre.

Rincer à contre-courant pendant 5 minutes, puis rincer à nouveau pendant 2 minutes.

Mettez la valve en mode filtration. Effectuez un lavage à contre-courant du filtre lorsque la pression dépasse 1,5 bar.

Frequently asked questions

VIDROMAR takes up more space than silica sand due to the difference in particle density and its Anti-Compaction Technology®. You will therefore need 20% less than the amount recommended by the manufacturer in the filter instructions.

Silica sand loses its filtration capacity in a short time due to the growth of a biofilm (bacterial colonies) between its grains, which creates preferential channels and clogging.

The absence of biofilm and the Anti-Compaction® technology make VIDROMAR one of the most efficient filter media on the market.

Yes, all standard filters can be used with VIDROMAR. If your filter does not have the globally harmonised nozzle opening size [0.35 +- 0.015 mm], we recommend replacing the nozzles with standard nozzles.

The combination of layers of different grain sizes within the filter is necessary when the filter media is not equipped with Anti-Compaction Technology®, in order to delay clogging and to be able to backwash correctly.

Thanks to its highly calibrated media grain curve, VIDROMAR does not require different layers in any type of filter. This also guarantees an indefinite service life.

VIDROMAR has been designed and produced specifically for use in water filters. To ensure maximum purity, only virgin glass is used. It is the only glass whose origin is controlled and which is guaranteed not to have come into contact with bacteria or any other contaminating material.

Unlike other glass filter media, it does not come from urban glass banks and is therefore the only one suitable for the filtration of water intended for human consumption.

Glass takes on its colour at the time of manufacture through the different chemicals, metals and oxides that are added to achieve each colour. Encapsulation at the molecular level does not change the properties of the glass and does not affect the filtering process. However, because the glass used for coloured filter media comes from glass banks and not directly from the manufacturer, it can contain all sorts of bacteria and contaminants that can end up in the water, making it unsafe for use in water filters for human consumption.

Thanks to its advantages and technical characteristics, VIDROMAR is currently used in more than 100,000 installations worldwide. It is mainly used in :

- Private pools

- Public swimming pools

- Advanced industrial facilities such as water treatment plants, water parks, nuclear facilities, desalination plants and aquaculture circuits, among others.

By definition, filtration is a mechanical process in which no other forces are involved. Unwanted particles are retained in a filter due to the interaction between the water flow and the filter medium. Due to its insulating nature, glass does not allow the free flow of electrons, so it cannot be “charged” or “activated”.

Other manufacturers claim that their glass is ‘activated’, but this has not been supported by any studies or demonstration.

Half fill the empty filter with water to protect the nozzles.

Fill the filter with 20% less VIDROMAR than recommended by the filter manufacturer.

Backflush for 5 minutes, then flush again for 2 minutes.

Switch the valve to filtration mode. Backwash the filter when the pressure exceeds 1.5 bar.

VIDROMAR is committed to sustainability and reducing its environmental footprint. This is why we work with FSC-certified packaging from the outset, thus avoiding the use of thousands of kilograms of plastic.

In addition, VIDROMAR is produced from recycled virgin glass and contributes to a significant reduction in energy and water consumption in swimming pools around the world.

And we continue to work every day to apply intelligent and sustainable solutions at every stage of production.

All you need to know,in our INFOCOM

Resources and downloads

We provide you with certifications, complete tests and data sheets for VIDROMAR glass filters.

- VIDROMAR Infocom

- IFTS Hi-Tech Glass Filter Media tests (original with comments)

- VIDROMAR full Bioexam test vs AFM ng vs ION Pure vs Astral

- Certification: BUREAU VERITAS UNE EN 12904

- Certification: BUREAU VERITAS Product / Production / Traceability / Absence of Free Silica

- VIDROMAR Sample kit

- Test: IFTS AFM ng original - with comments -

- Test: IFTS Glass Beads original - with comments -

- Test: VIDROMAR purity level

- Test: AFM ng purity level